Slip resistance is a critical factor when selecting floor tiles for areas with a high risk of slipping, such as swimming pools, bathrooms, public lobbies, or sloped surfaces. Evaluating slip resistance cannot rely on visual inspection alone; instead, it must be conducted using standardized international testing methods [1].

Currently, there are four commonly recognized testing methods worldwide. Each method reflects a different aspect of real-world usage. This article will help you understand each method in detail—including the test procedure, applicable standards, measurement scale, and appropriate applications.

Below are the four most commonly used slip resistance testing methods today

Pendulum Test (British Pendulum Tester):

Measures slip resistance through the energy loss of a rubber slider mounted on a swinging pendulum. Common in the UK, Australia, and Singapore.

Tribometer Test – DCOF (Dynamic Coefficient of Friction):

Measures the dynamic friction between tile surfaces and rubber soles using specialized devices. Common in the US and Canada.

Surface Roughness Test – Rz:

Evaluates surface texture to indirectly estimate slip resistance. Often used for quality control in manufacturing.

Standards: DIN 51130 (shod foot); DIN 51097 (barefoot)

Purpose: Assess slip resistance on inclined surfaces

Procedure: A person walks on a surface with increasing slope until slippage occurs

Measurement Scale:

DIN 51130: R9 to R13 (R13 = highest slip resistance, >35° angle)

DIN 51097: A, B, C (C = highest level for barefoot areas)

Advantages: Realistic simulation of human motion

Disadvantages: Costly, not practical on-site, depends on human subjectivity [1], [2]

Standards: BS EN 13036-4, ASTM E303, AS 4586

Purpose: Simulates heel strike and sliding on wet or dry surfaces

Procedure: A pendulum with a rubber slider swings across the tile surface, measuring energy loss

Measurement Scale (PTV – Pendulum Test Value):

25: High slip risk

25–35: Moderate risk

36–44: Moderate safety

≥45: High safety

Advantages: Represents real walking behavior; portable for field testing

Disadvantages: Sensitive to environmental conditions [1], [3]

Standards: ANSI A326.3 (USA); tested using BOT-3000E equipment

Purpose: Measures dynamic friction while walking on wet tiles

Procedure: The equipment drags a rubber pad across a wet surface and calculates the DCOF

Measurement Scale:

DCOF ≥ 0.42 (wet condition): considered safe under ANSI standard

Advantages: Accurate and quantifiable results

Disadvantages: Does not simulate human gait behavior; equipment is expensive [1], [4]

Standard: ISO 4287

Purpose: Evaluate texture to estimate slip potential

Procedure: A profilometer moves across the surface and records deviations

Measurement Scale:

Rz ≥ 10 µm: typically considered acceptable for slip resistance

Advantages: Fast and easy to apply at factories

Disadvantages: Does not account for real-life conditions (wetness, oil, slope) [1]

The Ramp Test is the most realistic method as it involves human subjects. It is ideal for inclined, oily, or wet areas such as industrial kitchens or swimming pools. However, due to its complexity and cost, it is rarely used outside Europe.

The Pendulum Test strikes a balance between practicality and accuracy. It is well-suited for field testing, providing objective results for both dry and wet conditions. Many countries use it as a legal or regulatory standard.

The Tribometer – DCOF test is particularly favored in the US for its clarity in defining thresholds (e.g., DCOF ≥ 0.42). Yet, it lacks real-world gait simulation and may over- or underestimate risk in complex environments.

The Surface Roughness Test – Rz is a useful quality control tool during manufacturing but should not be used as a standalone slip resistance assessment due to its limited environmental realism.

No single test method can fully assess slip resistance in all situations. Each method is designed for a different usage scenario. In practice, combining multiple indicators—such as R-Value (Ramp), DCOF (Tribometer), and PTV (Pendulum)—offers a more comprehensive understanding of tile safety.

For residential, commercial, or public spaces, stakeholders are encouraged to request certified slip resistance test results from at least one of the above methods—particularly DCOF or Pendulum, which are widely accepted across international markets.

[1] Tile Council of North America, TCNA Handbook for Ceramic, Glass, and Stone Tile Installation, 2024. [Online]. Available: https://www.calameo.com/read/006507186b2596f3525e4

[2] A. Terjék and A. Dudás, “Ceramic Floor Slipperiness Classification – A new approach for assessing slip resistance of ceramic tiles,” Construction and Building Materials, vol. 164, pp. 809–819, 2018. [Online]. Available: https://doi.org/10.1016/j.conbuildmat.2017.12.242

[3] ASTM International, “ASTM E303‑22: Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester,” 2022. [Online]. Available: https://www.astm.org/e0303-22.html

[4] Tile Council of North America, “ANSI A326.3‑2021: Dynamic Coefficient of Friction (DCOF) of Hard Surface Flooring Materials,” 2021. [Online]. Available: https://webstore.ansi.org/standards/tca/ansia3262021

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

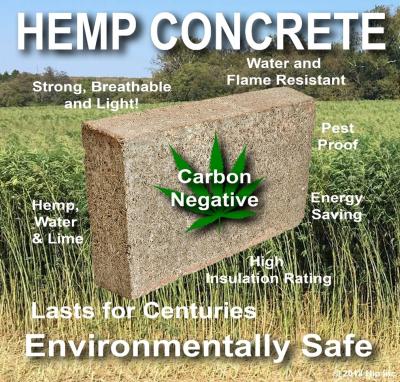

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.

The News 11/10/2025

Amid rapid urbanization and global climate change, architecture is not only construction but also the art of harmonizing people, the environment, and technology. The Bahrain World Trade Center (BWTC)—the iconic twin towers in Manama, Bahrain—is a vivid testament to this fusion. Completed in 2008, BWTC is not only the tallest building in Bahrain (240 meters) but also the first building in the world to integrate wind turbines into its primary structure, supplying renewable energy to itself [1]. This article explores the BWTC’s structural system and design principles, examining how it overcomes the challenges of a desert environment to become a convincing sustainable model for future cities. Through an academic lens, we will see that BWTC is not merely a building but a declaration of architectural creativity.