Permeable pavers are surface paving materials specifically designed to allow rainwater to seep through rather than run off as on conventional concrete or asphalt surfaces. [1]

Unlike traditional hard surfaces, permeable pavers limit surface runoff, reduce urban flooding, and filter contaminants such as dust, heavy metals, and pollutants directly on site. This green solution plays a key role in sustainable and eco-friendly urban stormwater management systems. [2]

The system typically includes five layers:

Made of interlocking concrete pavers.

Small gaps between pavers allow rainwater to pass through.

Designed to support the weight of vehicles and pedestrians.

A thin layer of fine aggregate (e.g., ASTM No. 8 gravel or clean sand).

Stabilizes the pavers and facilitates downward water flow.

Composed of medium-sized crushed stone (e.g., ASTM No. 57 or 40mm).

Functions as a preliminary filter and distributes water.

Made of large aggregate (e.g., ASTM No. 2 or equivalent).

High void content allows temporary water storage and facilitates gradual infiltration or drainage via piping systems.

Installed between the aggregate layers and the soil subgrade.

Prevents soil migration into the gravel, ensuring long-term permeability. [1]

During rainfall, water infiltrates through the gaps between the pavers rather than pooling on the surface. It then percolates through the underlying layers, which act as preliminary filters removing dirt, debris, and heavy metals.

The water is temporarily stored in the highly porous subbase layer. From here, two outcomes are possible:

If the underlying soil is permeable, water slowly infiltrates into the ground, helping to recharge groundwater.

If infiltration is limited or rainfall exceeds capacity, excess water is directed through an underground drainage system.

This process results in:

Reduced surface runoff and localized flooding.

Cleaner stormwater before discharge into the environment or ground.

Lower burden on municipal drainage systems and improved environmental quality.

Parking Lots: Implemented in public areas, schools, parks, and commercial centers to reduce runoff and flooding.

Pathways and Internal Roads: Slip-resistant and puddle-free surfaces ensure safer movement during rain or snow.

Residential and Industrial Access: When properly installed, permeable pavers can support heavy truck loads.

LEED Credit 6: Reduces stormwater runoff and pollution by increasing infiltration.

LEED Credit 7: Mitigates urban heat island effect through reflective, lighter-colored surfaces.

Groundwater Recharge: Allows rainwater to seep into the soil, reducing pressure on drainage systems.

Erosion and Thermal Control: Used along riverbanks and streams to minimize erosion and thermal pollution.

Proven effective in freeze–thaw environments; unlike traditional concrete, it does not crack.

Surface does not ice over as water is absorbed into the subsurface, enhancing winter safety.

Can substitute traditional stormwater systems, saving land and infrastructure costs.

Life-cycle cost is significantly lower than asphalt or concrete — one report shows a reduction from over $1 million to around $25,000 over 25 years. [3]

[1] "How Permeable Pavements Work," YouTube, 2016. [Online]. Available: https://www.youtube.com/watch?v=7LHPzybDWtc

[2] K. R. and J. Ball, "A Review of the Performance of Permeable Pavers," 2004. [Online]. Available: https://d1wqtxts1xzle7.cloudfront.net/83833768/A_Review_of_the_Performance_of_Permeable20220411-14227-p1tdge.pdf. [Accessed: Jul. 2025].

[3] J. Houle, M. M. B. P., R. R. P., P. D. T., and P. B. P., "Permeable Paver Research Summary," Feb. 2003. [Online]. Available: http://americantrails.pairserver.com/files/pdf/PermPavers.PDF. [Accessed: Jul. 2025].

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

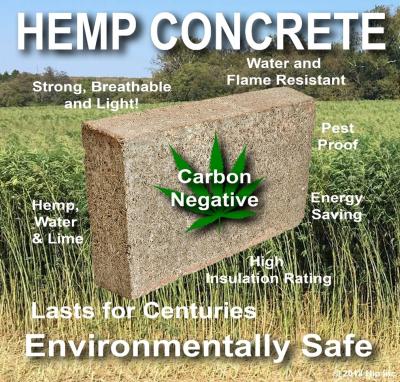

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.

The News 11/10/2025

Amid rapid urbanization and global climate change, architecture is not only construction but also the art of harmonizing people, the environment, and technology. The Bahrain World Trade Center (BWTC)—the iconic twin towers in Manama, Bahrain—is a vivid testament to this fusion. Completed in 2008, BWTC is not only the tallest building in Bahrain (240 meters) but also the first building in the world to integrate wind turbines into its primary structure, supplying renewable energy to itself [1]. This article explores the BWTC’s structural system and design principles, examining how it overcomes the challenges of a desert environment to become a convincing sustainable model for future cities. Through an academic lens, we will see that BWTC is not merely a building but a declaration of architectural creativity.