What is Computer Vision?

Computer vision is a technology that allows machines to automatically recognize and describe images accurately and efficiently. Today, computer systems have access to a vast amount of image and video data derived from or generated by smartphones, traffic cameras, security systems, and other devices. Applications of computer vision use artificial intelligence and machine learning (AI/ML) to process this data precisely for object identification and facial recognition, as well as for classification, recommendation, monitoring, and detection tasks [1].

Image Recognition:

This is one of the most common applications of artificial intelligence in the field of computer vision. This technology enables systems to identify and distinguish a specific object, person, or action in an image or video. For example, it can identify animals in the wild, distinguish types of fruits in a supermarket, or detect situations in security surveillance systems.

Object Detection:

This task extends image recognition by not only identifying one object but also recognizing multiple objects in a single image and more importantly, determining their exact locations using bounding boxes. This technology is widely applied, especially in self-driving car systems, which must continuously recognize all vehicles, pedestrians, traffic signs, or other objects to make precise decisions ensuring safety.

Image Segmentation:

This technology goes further in image analysis by dividing the image into different regions or segments based on features such as color, shape, or texture. This helps reduce complexity, clarifies parts of the image, and facilitates easier processing and analysis. In medicine, image segmentation plays a crucial role in identifying pathological areas in diagnostic images, such as segmenting tissues, organs, or cancers in CT or MRI scans.

Facial Recognition:

This technology enables the system to identify or verify a person’s identity based on facial features in images or videos. It is widely applied in access control systems, security monitoring, and personalized services such as phone unlocking or automatic attendance systems in schools or businesses.

Motion Analysis:

This is a technology for tracking the trajectory and behavior of moving objects in video. It enables the detection, analysis, and prediction of the motion of objects accurately. Motion analysis is crucial in fields such as security, surveillance, and sports, helping with tactical analysis, detecting abnormal behaviors, or tracking athletes during competitions.

Machine Vision:

This involves integrating artificial intelligence with robotics, allowing robots or automated systems to process image data to perform tasks such as product quality inspection, sorting goods, or guiding precise movements on production lines. In industry, this system improves efficiency, minimizes errors, and optimizes automation processes.

Image Segmentation plays an important role in determining the mortar ratio of aggregate in construction and material science contexts. Specifically, its functions include:

Distinguishing components in the image: Separating parts of the image such as mortar, aggregates (stones or grains), and other components based on color, brightness, or morphological features.

Determining the area of each component: After segmentation, it calculates the area of distinct regions corresponding to mortar and aggregates to obtain accurate data on the proportion of each component in the sample.

Optimizing analysis accuracy: Helps eliminate noise or unwanted parts to ensure that the measurements of mortar and aggregate ratios are accurate and reliable.

Supporting mortar ratio calculation: Based on the segmented area or volume data, the mortar-to-aggregate or total sample ratio can be calculated in percentage or proportion form.

Bibliography

[1] Amazon, “Thị giác máy tính là gì” [Online]. Available: https://aws.amazon.com/vi/what-is/computer-vision/

[2] 200LAB, “Computer Vision là gì? Những ứng dụng của Thị giác máy tính,” [Online]. Available: https://200lab.io/blog/computer-vision-la-gi

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

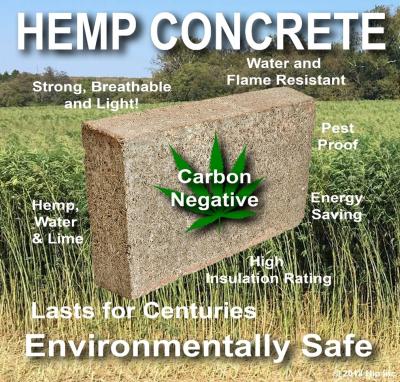

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.

The News 11/10/2025

Amid rapid urbanization and global climate change, architecture is not only construction but also the art of harmonizing people, the environment, and technology. The Bahrain World Trade Center (BWTC)—the iconic twin towers in Manama, Bahrain—is a vivid testament to this fusion. Completed in 2008, BWTC is not only the tallest building in Bahrain (240 meters) but also the first building in the world to integrate wind turbines into its primary structure, supplying renewable energy to itself [1]. This article explores the BWTC’s structural system and design principles, examining how it overcomes the challenges of a desert environment to become a convincing sustainable model for future cities. Through an academic lens, we will see that BWTC is not merely a building but a declaration of architectural creativity.