Shimizu Corporation (清水建設株式会社) is one of the largest and oldest construction groups in Japan, founded in 1804 by Kisuke Shimizu I. From its beginnings as a small carpentry workshop, Shimizu has grown into a global corporation with over 11,000 employees in Japan and around 21,000 worldwide. Headquartered in Kyobashi, Tokyo, the company operates across various fields, including industrial and civil construction, real estate development, design, infrastructure engineering, and building maintenance services. Shimizu is particularly renowned for its focus on sustainable development, exemplified by the “SHIMZ Beyond Zero 2050” strategy, which aims to achieve carbon neutrality, promote material recycling, and apply environmentally friendly construction technologies.

In its pursuit of sustainable building materials, Shimizu has placed particular emphasis on reducing emissions from cement, the largest source of CO₂ in traditional concrete. Instead of relying solely on hydrated cement, the company developed carbon-negative concrete technology by incorporating biochar, a product of biomass carbonization. This biochar is processed into fine powder or coarse particles and added directly into the concrete mix as a special additive.

The primary raw material for biochar production is sawdust, a byproduct of wood processing. Typically, the carbon in sawdust would be released into the atmosphere as CO₂ through natural decomposition or combustion. However, through carbonization, most of the carbon in sawdust is transformed into a stable form that is resistant to decomposition and unlikely to emit CO₂ unless exposed to extremely high temperatures. Thanks to this process, the fixed carbon content of dried biochar can reach up to around 90%, enabling long-term storage of a significant amount of carbon within the material.

In experimental applications, Shimizu combined two forms of biochar: fine powder with particle sizes under 1 mm and coarse particles between 2–5 mm. The fine powder was used to replace part of the fine aggregate in the concrete, while the coarse particles were mixed to optimize mechanical properties, ensuring both carbon fixation capacity and structural durability.

Shimizu’s carbon-negative concrete technology, SUSMICS-C, developed through the use of biochar to capture and store carbon within concrete, has gone beyond the research stage and been applied in real-world projects in Japan. According to Shimizu, this eco-friendly concrete was first used in an actual construction project on February 21, 2023. During the project, biochar was incorporated in two forms: coarse particles of approximately 2–5 mm and fine powder smaller than 1 mm, which replaced part of the fine aggregate and enhanced carbon sequestration. The application of SUSMICS-C in this construction project marked a significant milestone, demonstrating the feasibility and commercial potential of carbon-negative concrete technology within the Japanese construction industry.

In the SUSMICS-C technology, Shimizu employs biochar as the main component for carbon sequestration in concrete. Biochar is processed into two forms, each serving different functions in the concrete mixture: fine powder with a particle size of less than 1 mm, and coarse particles sized between 2 and 5 mm. Fine biochar powder is used to partially replace traditional fine aggregates, increasing the surface area for carbon fixation within the concrete mass, while coarse particles help maintain the structure, support mechanical strength, and ensure bond integrity.

In addition to biochar, the mixture includes blast furnace cement (type B) as the main binder, along with other additives to adjust workability, plasticity, impermeability, and stability of the concrete. With the appropriate dosage and proper mixing ratios of biochar, SUSMICS-C concrete achieves stable carbon sequestration while still meeting standards for strength and mechanical performance.

The production of carbon-negative concrete using SUSMICS-C involves a sequence of scientifically controlled steps to ensure effective CO₂ fixation and long-term material sustainability. First, biomass materials such as sawdust and wood residues are carbonized under low-oxygen conditions to produce biochar. This process transforms the organic carbon in biomass into a stable form that is resistant to decomposition or CO₂ release.

The resulting biochar is then processed into two forms: fine powder (particle size 1 mm) and coarse particles (2–5 mm), optimizing both carbon storage and mechanical properties of the concrete. These components are then mixed with blast furnace cement, aggregates, and specialized admixtures to create a workable concrete mixture with proper plasticity. Throughout the mixing process, Shimizu applies strict quality control to ensure uniform distribution of biochar within the concrete mass, thereby maintaining the required compressive strength while maximizing carbon absorption and long-term storage efficiency.

[1] Shimizu Corporation, “Company Outline,” Shimizu Corporation. [Online]. Available: https://www.shimz.co.jp/company/about/outline/. [Accessed: Sept. 20, 2025].

[2] Shimizu Corporation, “技術・ソリューション SUSMICS-C バイオ炭コンクリート,” Shimizu Corporation. [Online]. Available: https://www.shimz.co.jp/solution/tech383/. [Accessed: Sept. 20, 2025].

[3] Shimizu Corporation, “News Release: Development of Carbon Negative Resin Concrete,” Shimizu Corporation, Jun. 21, 2023. [Online]. Available: https://www.shimz.co.jp/company/about/news-release/2023/2022061.html. [Accessed: Sept. 20, 2025].

[4] Shimizu Corporation, “News Release: Shimizu Develops Biochar Concrete,” Shimizu Corporation, 2022. [Online]. Available: https://www.shimz.co.jp/company/about/news-release/2022/2022017.html. [Accessed: Sept. 20, 2025].

[5] Shimizu Corporation, “News Release: Verification of Carbon Negative Concrete in Actual Construction,” Shimizu Corporation, 2024. [Online]. Available: https://www.shimz.co.jp/company/about/news-release/2024/2024044.html. [Accessed: Sept. 20, 2025].

[6] World Construction Today, “Shimizu Corporation develops carbon-negative resin concrete applied for the first time in Fukuoka City Road Project,” World Construction Today. [Online]. Available: https://www.worldconstructiontoday.com/news/shimizu-corporation-develops-carbon-negative-resin-concrete-applied-for-the-first-time-in-fukuoka-city-road-project/. [Accessed: Sept. 20, 2025].

The News 14/12/2025

Architectural Digest gợi ý Cloud Dancer phù hợp với plush fabrics và những hình khối “mềm”, tránh cảm giác cứng/rigid; họ liên hệ nó với cảm giác “weightless fullness” (nhẹ nhưng đầy) [3]. Đây là cơ hội cho các dòng vải bọc, rèm, thảm, bedding: màu trắng ngà làm nổi sợi dệt và tạo cảm giác chạm “ấm”.Pantone has announced the PANTONE 11-4201 Cloud Dancer as the Color of the Year 2026: a "buoyant" and balanced white, described as a whisper of peace in the midst of a noisy world. This is also the first time Pantone has chosen a white color since the "Color of the Year" program began in 1999. Pantone calls Cloud Dancer a "lofty/billowy" white tone that has a relaxing feel, giving the mind more space to create and innovate [1].

The News 04/12/2025

The Netherlands is one of the most vulnerable countries to climate change, with about a third of its area lying below sea level and the rest regularly at risk of flooding. As sea levels are forecast to continue to rise and extreme rains increase, the government is not only strengthening dikes and tidal culverts, but also testing new adaptation models. Floating housing in Amsterdam – typically the Waterbuurt and Schoonschip districts – is seen as "urban laboratories" for a new way of living: not only fighting floods, but actively living with water. In parallel with climate pressures, Amsterdam faces a shortage of housing and scarce land funds. The expansion of the city to the water helps solve two problems at the same time: increasing the supply of housing without encroaching on more land, and at the same time testing an urban model that is able to adapt to flooding and sea level rise.

The News 20/11/2025

Kampung Admiralty - the project that won the "Building of the Year 2018" award at the World Architecture Festival - is a clear demonstration of smart tropical green architecture. With a three-storey "club sandwich" design, a natural ventilation system that saves 13% of cooling energy, and a 125% greening rate, this project opens up many valuable lessons for Vietnamese urban projects in the context of climate change.

The News 10/11/2025

In the midst of the hustle and bustle of urban life, many Vietnamese families are looking for a different living space – where they can enjoy modernity without being far from nature. Tropical Modern villa architecture is the perfect answer to this need. Not only an aesthetic trend, this is also a smart design philosophy, harmoniously combining technology, local materials and Vietnam's typical tropical climate.

The News 25/10/2025

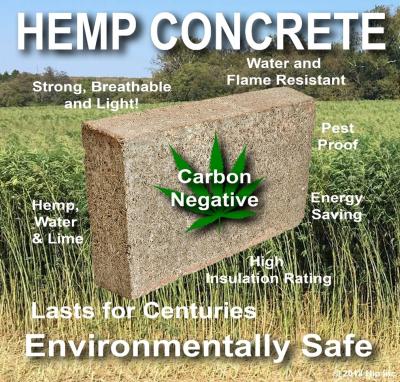

Hemp-lime (hempcrete) is a non-load-bearing covering material consisting of a hemp wood core (hemp shiv/hurd) combined with a lime-based adhesive, outstanding for its insulation – moisture conditioning – indoor environmental durability; in particular, IRC 2024 – Appendix BL has established a normative line applicable to low-rise housing, strengthening the technical-legal feasibility of this biomaterial.

The News 11/10/2025

Amid rapid urbanization and global climate change, architecture is not only construction but also the art of harmonizing people, the environment, and technology. The Bahrain World Trade Center (BWTC)—the iconic twin towers in Manama, Bahrain—is a vivid testament to this fusion. Completed in 2008, BWTC is not only the tallest building in Bahrain (240 meters) but also the first building in the world to integrate wind turbines into its primary structure, supplying renewable energy to itself [1]. This article explores the BWTC’s structural system and design principles, examining how it overcomes the challenges of a desert environment to become a convincing sustainable model for future cities. Through an academic lens, we will see that BWTC is not merely a building but a declaration of architectural creativity.